The Solutions

As a result of COVID-19, LCPS tasked CMTA with renovating six of their oldest facilities, Aldie Elementary school, Banneker Elementary School, Catoctin Elementary School, Middleburg Charter Academy, Broad Run High School and Loudoun Valley High School, to provide outside air ventilation at levels meeting current standards and modernize the buildings’ energy and envelope systems. Working closely with LCPS staff, CMTA evaluated multiple options prior to selecting the most cost-effective and energy-efficient HVAC solution for each building.

Three of the six facilities underwent complete demolition and replacement of their HVAC systems. For Aldie and Banneker Elementary Schools, the project included replacing the inefficient fuel oil-based steam boiler system and window AC units with a geothermal water source heat pump and dedicated outdoor air system (DOAS). All building exhaust streams were re-routed to the DOAS. Multiple console heat pumps replaced single radiators in spaces for resiliency and provided the ability to stage equipment, further increasing efficiency. New electrical switchgears, which replaced obsolete equipment with hard to source parts, were installed to support the new mechanical systems.

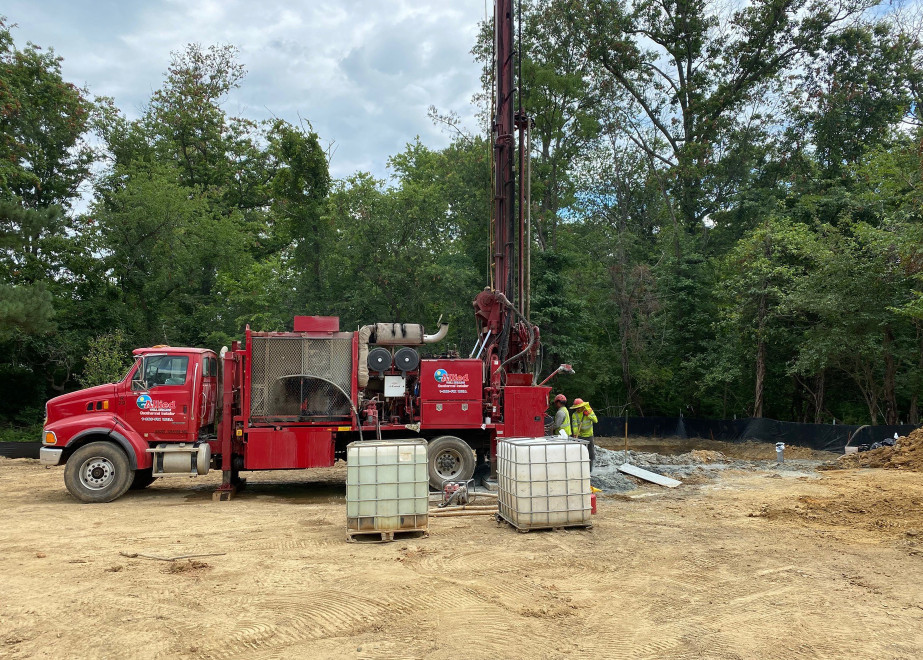

At Aldie Elementary School, the GSHP system wellfield was initially designed to be in the open field south of the building. However, after the test well in this location was permitted and drilled, the county revoked the permit, due to the wellfield being located within a flood zone. As a result, the project team worked together to redesign the wellfield in another open space north of the building. This required routing the horizontal piping under the building’s stacked stone foundation through directional boring and installing the header within the crawl space. Remarkably, all of this was accomplished within a month to allow construction completion over the summer of 2021, so the building would be ready for classes to resume.

The historic buildings needed several improvements to tighten the existing envelope and reduce energy loss due to infiltration. The project involved the addition of attic insulation where none previously existed. The crawl spaces were improved by adding a vapor barrier, sealing the existing vents, and installing mechanical ventilation that is only enabled as required.

CMTA was challenged to develop an alternative solution after the local Historic District Review Board prohibited replacing the existing single-pane wooden windows with new double-pane, low-E thermal windows. CMTA redeveloped this measure to include restoring the existing wood windows, adding new weather-stripping on all sashes, and installing the interior fixed panel tempered glass inserts to match the initial window plan’s thermal performance.

Only the original portion of Catoctin Elementary School, Broad Run High School, and Loudoun Valley High School required ventilation improvements. Given site constraints and constructability issues, substantially more efficient but traditional HVAC systems were installed. This scope of work included the installation of dedicated outside air systems, replacement of fan-coil units, and multiple replacements of rooftop units. A new fire suppression system was installed at one facility in conjunction with the new HVAC system. A new energy management system with sequences, schedules and set points that optimized the operation of the HVAC systems was installed at all six of the schools.

Additionally, all interior and exterior lighting fixtures were upgraded to LED lighting at four elementary schools. Offices and classrooms received multi-level switching and dimming capabilities. Lithium-ion battery back-up power was provided for fixtures in every classroom and means of egress. A recent roof replacement at Catoctin Elementary School made it a prime candidate for a 244-kW solar photovoltaic (PV) system to be included within the project.